A.Yu. Shabanov, Yu.V. Galyshev, A.B. Zaytsev, S.V. Butorov

20

Engineering Journal: Science and Innovation

# 11·2017

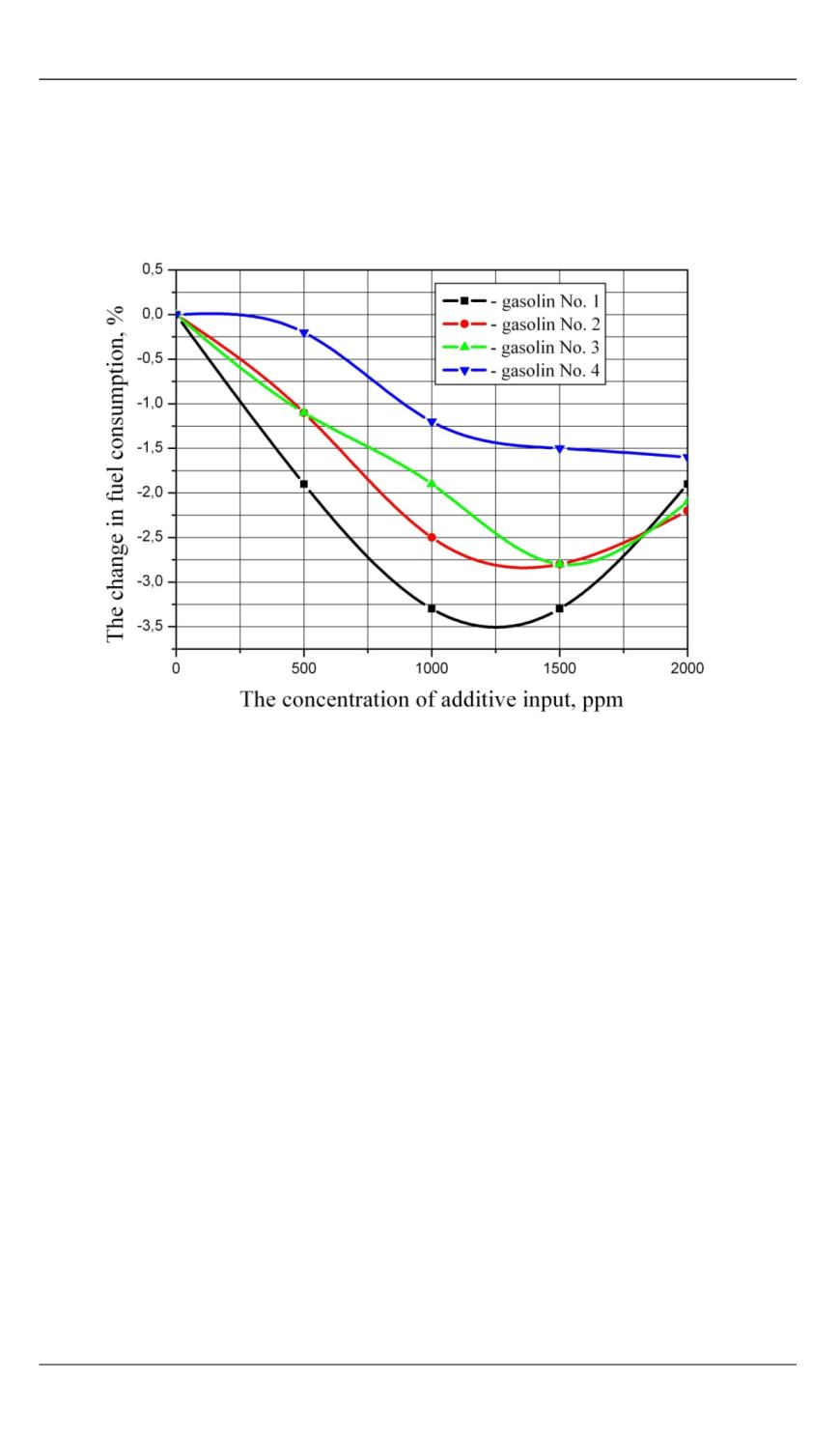

Some results of the performed tests is given below. Fig. 4 shows the

dependence of the relative change of averaged fuel specific consumption

of the engine when operating on gasoline containing the additive, the con-

centration of its input in the fuel.

Fig. 4.

The dependence of the relative change in specific fuel consump-

tion the concentration of the input multifunctional additives

In Fig. 4 the graphs show a pronounced dependence of the optimal

additive concentration at which the maximum energy-saving effect, from

the group composition of gasoline. Also it is clearly seen the dependence

of this parameter from the content in oxygenated gasoline component. So,

for gasoline samples No. 1 and No. 2 not containing in the composition of

oxygenates, the value of an optimal concentration close (about 1300 ppm),

which exceeds the stated manufacturer of the additive (1000 ppm). For

gasoline containing bound oxygen, optimum concentration is shifted in a

big way. So, for sample No. 3, the best results are obtained when the con-

centration 1600 ppm of the additive. Moreover, for gasoline No. 4 in the

studied range of concentrations the optimum was not determined, that is, it

is achieved at the concentration of the additive substantially in excess of

2000 ppm.

Also the curves in Fig. 4 show the effect of fuel composition on the

efficiency of the activator burning. The greatest effect (about 3.5 % reduc-

tion in fuel consumption relative to operation of the engine on base gaso-

line) obtained at the fuels, based on which the base gasoline No. 1, con-