Features of the detergent additive behavior in gasolines of different group composition

Engineering Journal: Science and Innovation

# 11·2017 19

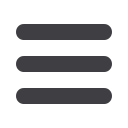

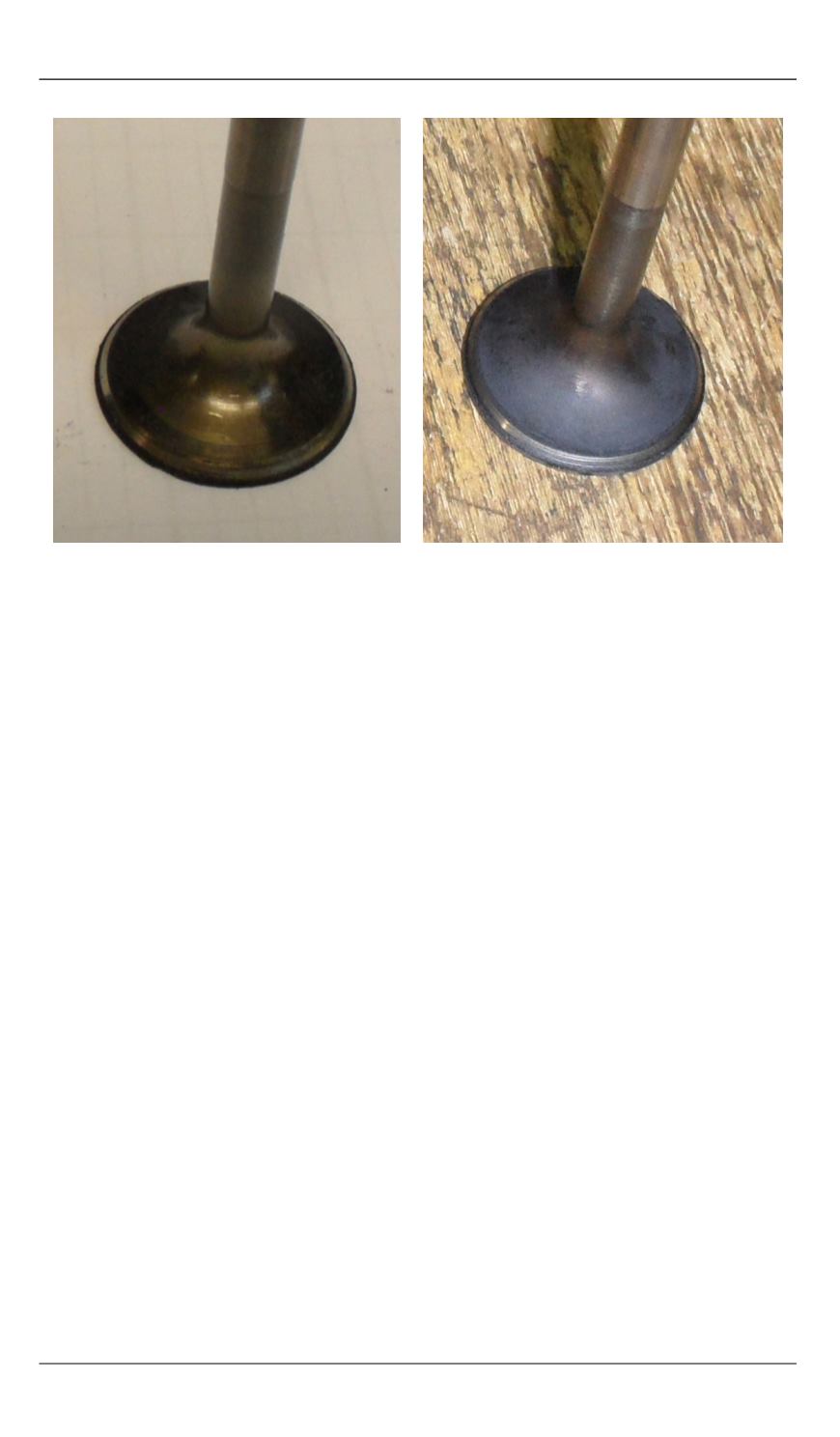

а

b

Fig. 3.

Deposits formed on the surface of the intake valve the tests of petrol No. 1 with

detergent additive (

a

) and without cleaning additives (

b

)

In the process of implementation of the second phase of work has

been carried out engine bench tests of the engine during its operation on

the samples of all four types of base gasolines with addition of multifunc-

tional additive in concentrations of 0, 500, 1000, 1500 and 2000 ppm. To

exclude the factor of the work of detergent additive component was not

allowed long operation of the engine on each fuel sample. The tests were

carried out on the engine, subjected to a special cleaning procedure, which

was removed sediments and contamination on the surfaces of the combus-

tion chamber, intake and exhaust systems accumulated in previous opera-

tion. The test results were obtained information about the influence of the

activator of fuel burning, forming part of a multifunctional additive to mo-

tor gasoline indicators of different group compositions.

Each test cycle included the following steps:

•

start-engine warm up, the time between a fixed mode for 20

minutes;

•

removing performance of the engine (engine speed, torque, instanta-

neous fuel consumption, contents in the exhaust gas component toxic: car-

bon monoxide, residual hydrocarbons CH, nitrogen oxides NO

x

and car-

bon dioxide CO

2

mixture, exhaust gas temperature) on the ten modes of

the two load characteristics in the operational range of the engine;

•

processing of test results with the conversion to standard atmospher-

ic conditions, the calculation of the average efficiency of the engine and

exhaust toxicity.