Features of the detergent additive behavior in gasolines of different group composition

Engineering Journal: Science and Innovation

# 11·2017 15

As follows from the results of determination of physico-chemical

characteristics of the base gasoline and samples of No. 1–3 belong to envi-

ronmental class K5 and fully comply with the requirements of Technical

regulations of the Customs Union TR CU 013/2011. Sample No. 4 does

not meet these requirements in composition (the presence of methanol),

mass fraction of oxygen and sulfur. It is a typical representative of gas

condensate of baseline gasoline, frequently used part of the fuel compa-

nies with a low turnover of fuel. Despite the illegitimacy of the composi-

tion of this sample of gasoline, it was decided to leave it in the study to

expand the range of parameters of the group composition of the fuel. The

results of the extended analysis of hydrocarbon composition of the sam-

ples of the base fuels represented in table 2.

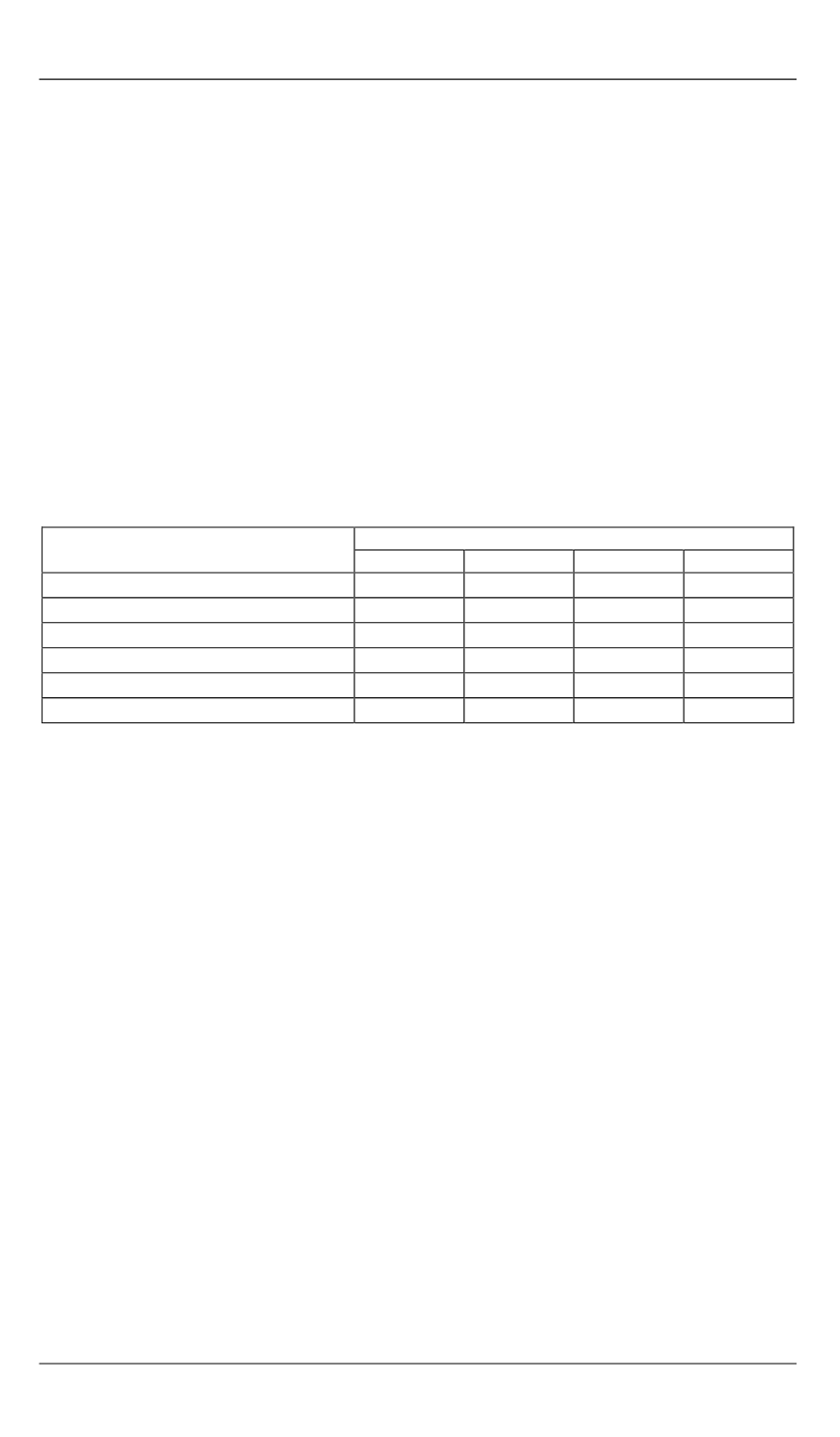

Table 2

The content of hydrocarbons of certain groups

in the studied samples of the base gasoline, % v/v

The group of hydrocarbons

A sample of gasoline

No. 1

No. 2

No. 3

No. 4

N-paraffin

11.43

12.04

12.55

18.47

Isoparaffin

47.23

48.54

40.54

31.43

Aromatic

34.87

33.04

25.88

16.34

Naphthenic

3.92

5.26

5.14

10.14

Olefin

2.55

0.42

4.18

2.08

Oxygenates

0

0.70

11.71

21.54

Tests were successively conducted for each sample of gasoline, then

for the same gasoline with multifunctional additives introduced into the

fuel at a concentration recommended by the manufacturer (1000 ppm).

For testing we used a motor stand with gasoline 16-valves a fuel injected

engine VAZ-2112 (4H 8.2/7.1) capacity 68 kW at rpm

n

= 5600 rpm.

Test procedure each sample of gasoline included the following stages

[9, 10]:

•

partial disassembly of the engine, weighing the weight of the control

elements (valves, spark plugs, injectors), Assembly, installation stand;

•

reference contamination — development on a fixed mode, 20 litres

special dirt mixture forming on the surfaces of the combustion chamber,

the fuel and intake systems of the engine starting of the deposition layer;

•

repeated partial disassembly, the determination of the initial mass of

sediments Assembly;

•

the initial lifting of the performance of the engine for a given pro-

gram with the measurement of instantaneous fuel consumption and toxici-

ty of exhaust gases on the load characteristics in the operational range of

the engine. It is not allowed to work the engine at high loads to exclude

the factor self-cleaning temperature of the engine;

•

holding a twenty-hour test cycle for variable modes of the subject

gasoline;